Marabu Textil Soft Linol Print & Colouring set

1703000000081

In relief printing, the printing areas are raised, which means that only the raised lines, gutters or surfaces of the printing plate are printed. The soft printing plate is very easy to use. It is a direct printing process, i.e. the printing plate transfers the ink directly onto the fabric. Therefore, the motif has to be its mirror image on the printing plate. Transparent watercolours are diluted with water and applied to the fabric with a wet brush. Water-based, saliva-resistant, washable to 40 °C, and soft to the touch. For light-coloured fabrics free of finishes and fabric conditioners (max. 20 % synthetic fibre). After drying, fix in the oven (150 °C/8 minutes), or iron for 3 minutes without steam. Stir paints before use and wash tools after use in water.

Contents: 1 x Textil Print 100 ml (Carbon black 974), 2 x Textil Aquarelle 15 ml (Lemon 020, Magenta 014), 1 x foam roller (60 mm), 1 x brush Marabu Universal round size 12, 1 x cutter with 2 blades (size 2 and 5), 1 x soft printing plate (Factis rubber carving block (155 x 90 x 7 mm)), 1 x brochure

2. Take up ink with the foam roller and roll onto the printing plate. The raised motif needs to be completely covered with a thin layer of ink.

3. Position the printing plate on the fabric and press it down applying slight pressure. Carefully remove the plate from the fabric. When printing is complete, quickly clean the printing plate with water and allow it to dry.

4. After drying, fix the fabric in the oven (8 minutes / 150 °C) or iron without steam for 3 minutes. Use a sponge to thoroughly moisten the area on which the watercolour motif is to be painted. The wetter the fabric, the more the watercolour will keep flowing. Or use the brush to paint the watercolour onto the fabric. The wetter the brush, the more the paint will keep flowing. For drying and fixing, place the damp motif flat on baking paper and then in the oven (8 minutes / 150 °C) fixing, the fabric is washable up to 40 °C.

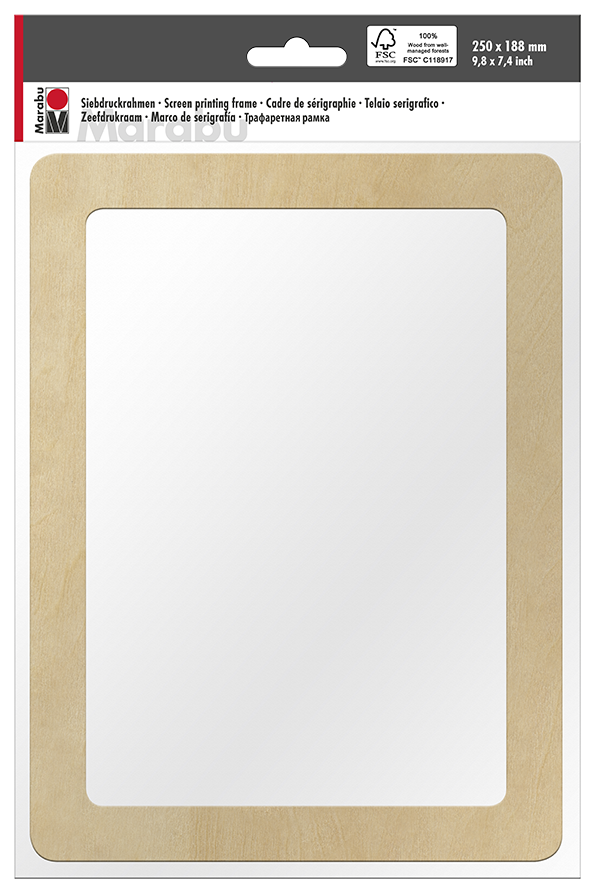

Screen printing is a method of printing that involves forcing the printing ink through a fi nely woven mesh onto the fabric using a squeegee. In the areas of the fabric where no ink is to be printed, according to the printed image, the openings of the mesh are made impermeable to ink. The motif is cut out and can then be reproduced. Paper stencilling is a particularly convenient method of working. All you need is a screen, a stencil, a cutter, some adhesive tape, a squeegee, and the printing ink TEXTIL PRINT.

Relief printing with Marabu TEXTIL PRINTPrinting with Marabu Textil Print

You can of course use a number of colours for printing, e.g. the background can have a different colour to the print motif. The printing plate can also be rollered with several colours. A single motif can be printed in different colours.