Marabu to be climate neutral from July 2021

Green milestone in the company's history - with PROJECT GREEN, the paint manufacturer will be climate neutral by the middle of the year.

Marabu is one of the first paint manufacturers to achieve climate neutrality. All Marabu Business Units will, where possible, make a specific contribution to achieve the 17 United Nations Sustainable Development Goals (SDGs) with PROJECT GREEN and thus participate in the Green Deal. With this milestone, Marabu is once again one step ahead of time.

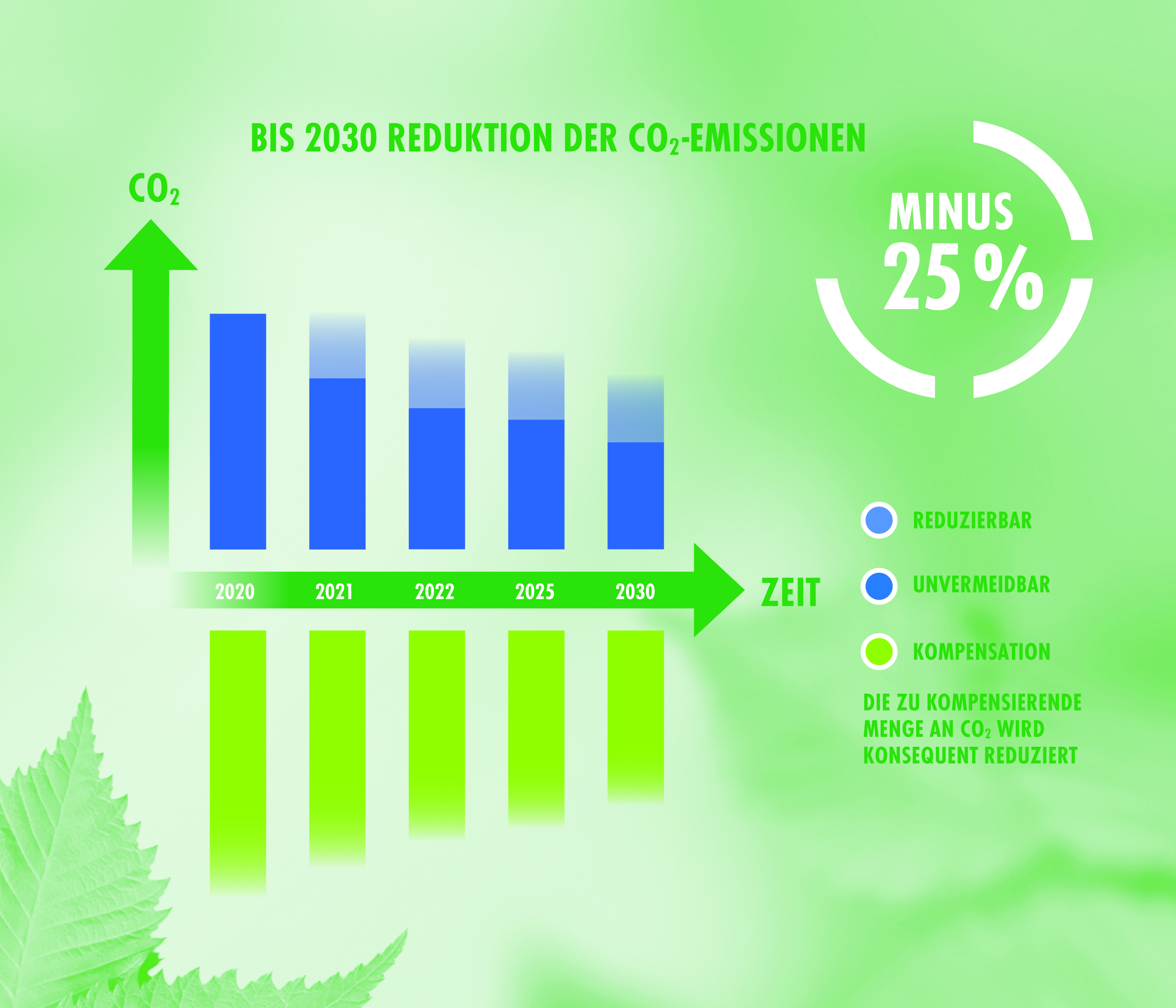

"We are safeguarding the future of coming generations and are proud that we have managed to be a climate neutral company from July 2021 with the Tamm and Bietigheim sites. And all our products, whether printing inks or creative colours, are climate neutral, too," explains York Boeder, CEO Executive Committee. "Our so-called PROJECT GREEN combines all measures that are taking us on our journey to climate neutrality. Climate protection is a particular concern for us, to which we have firmly committed ourselves to within the scope of an extensive sustainability strategy. In accordance with our Marabu Green Deal, we avoid and reduce emissions wherever possible, e.g. by using green electricity, energy-saving schemes, mobility concepts or environmentally friendly materials. We offset all unavoidable CO2 emissions by supporting internationally certified climate protection projects. We are continually implementing measures to improve our carbon footprint and update them annually to make their success measurable. We have therefore set ourselves the active goal of reducing our CO2 emissions by another 25 % by 2030."

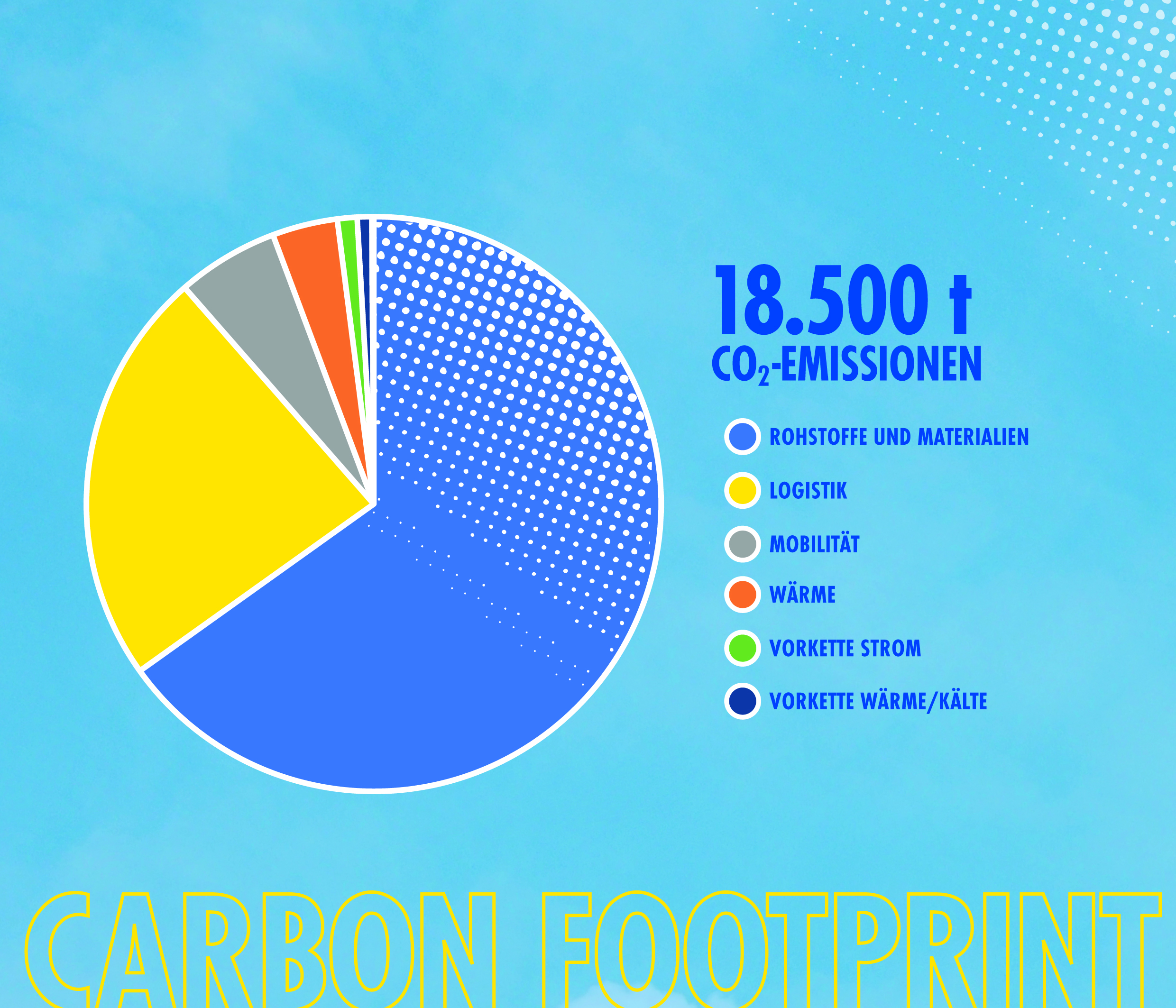

For decades, Marabu has invested in the research and development of safe production processes, environmentally friendly products and clean technologies with the aim of preserving the natural environment. Marabu has worked with Climate Partner to analyze all of the CO2 emissions from the sites in Tamm and Bietigheim and determine its carbon footprint. Including all product-related factors such as raw materials and logistics, Marabu currently generates approx. 18,500 tonnes of unavoidable CO2 emissions. This value is the positive result of a number of climate-friendly measures pursued by Marabu, such as the early switch to green electricity in 2007.

Energy - by switching to green electricity from hydropower, we eliminate almost 2,000 tonnes of CO2 every year, the equivalent of the annual CO2 footprint of 175 German citizens. By landscaping roofs we barely need any air-conditioning. We are constantly investing in renewable projects for saving energy in other areas too, such as the switch to modern lighting systems.

Mobility - Electromobility is the future. In view of this, we are continuously investing in the migration of our company vehicles to electric and hybrid cars as well as in e-charging stations. We support home office and ‘cycle to work’ initiatives. We are replacing laborious business trips with productive online conferences. Where on-site visits are unavoidable, we always minimize the number of travellers. Green modes of transport like train and public transport enable us to largely eliminate domestic and international flights.

Production - in our production facilities, we use renewable energies and resource-efficient production processes. We use water treatment and solvent recovery as well as open-air cooling and low power cooling systems to avoid environmentally damaging coolants.

Our packaging protects the products, presents the contents and is impressively durable. Whether glass, aluminium, cardboard or plastic, the use is carefully weighed up according to the principle: as little material as necessary. As much recycling as possible. That's why we prefer monomaterials and materials with a high recycled content.

Raw materials - in our in-house laboratories, experts conduct daily research to replace critical substances with environmentally friendly alternatives for both new and existing products. We also extend this environmental commitment from Marabu to our upstream supply chains.

Transporting - green transportation is already part of our climate strategy. Climate-neutral freight carriers and lower-emission transport methods like shipping or road transport replace air freight wherever possible. And at all Marabu sites, consistent waste management is practiced as a matter of course.

Product technology - we have been developing modern, low-emission products for decades. Tests in independent laboratories and test centers confirm our commitment to responsible products. The proportion of water based systems for our creative colours is already over 90% plus we are working hard to develop new formulations based on renewable raw materials. In the printing inks division, we expect to be able to increase the proportion of water based systems by more than 300% over the next 5 years. In addition, the well-established UV curable ink systems and, in particular, LED curable systems help us increasingly to avoid ceramic paints and solvent-containing systems, thereby further reducing VOC emissions generated by the printing process.

We offset unavoidable CO2 emissions with selected climate protection projects. All projects are certified to the Gold Standard CER and meet particularly high requirements. With a branch office in Brazil and a production site in Paraguay, we feel a strong connection to South America. The idea behind the forest conservation project in Portel is to support the Ribeirinhos, one of the poorest populations in the Amazon, and sustainably protect the rainforests. If its deforestation continues, millions of tonnes of CO2 will be incessantly released. By giving the Ribeirinhos the official land rights, agricultural companies can no longer occupy the area. This rescues about 3,000 hectares of rainforest from destruction each year and enables them to be managed in a resource-conserving manner.

With a subsidiary in Shanghai and strong business partnerships throughout Asia, we maintain close communications with the continent. In China, we support the biogas project in Haikou. And successfully so: 15,555 small farmers have so far been able to set up small biogas systems for their own use. The resulting gas covers all of a household’s heating requirements.

As a leading printing ink manufacturer for the packaging industry, we feel a particular sense of responsibility towards the protection of the oceans. Over 8 million tonnes of plastic waste end up in the world's seas and oceans every year. Through Project Plastic Bank, people in Haiti, Indonesia, Brazil or the Philippines collect plastic waste and exchange it at local collection points for food, drinking water, mobile phone credit or school fees. The collected plastic is carefully reintegrated into the product cycle.

Our climate protection projects therefore not only save CO2, but also contribute to sustainable local development.

Transparency and credibility - environmental and climate protection is not only a central topic in public debate. For almost all people it is also an important factor in their lives, and especially in their purchases. The label ‘climate neutral´ represents transparent and credible climate protection. Our carbon footprint as well as our climate protection projects can be tracked via an ID number and the Climate Partner ID tracking system. But this is only the beginning - our journey to climate neutrality is far from complete. Detailed information on Marabu PROJECT GREEN can be found in our new brochure and on: www.marabu-creative.com/en/project-green/

DOWNLOADS

-

Press_News_Marabu_to_be_climate_neutral_290621

-

Marabu_Project_Green_Teamfoto_P1 (1)

-

York_Boeder_CEO_Marabu_Creative_Foto_Brochure_Project_Green

-

Marabu_Creative_Bietigheim_Bissingen_Gebauede

-

Marabu_Headquarter_Tamm

-

Marabu_Klimaneutralitaet Project Green Logo

-

Marabu_Klimaneutralität_Projekt_Green_Diagramme_3

-

Marabu_Klimaneutralität_Projekt_Green_Diagramme_2

-

Marabu_Klimaneutralität_Projekt_Green_Diagramme_1

-

Marabu_Project_Green_BRAZIL_CP1086_P2 (1)

-

Marabu_Project_Green_CHINA_CP1237_P3 (1)

-

-

Marabu to be climate neutral from July 2021